Wolff® Scissors

Wolff Industries, Inc. proudly leads the market as the sole manufacturer of industrial-grade, plastic-handled stamped shears in the United States, crafting them at our state-of-the-art Wolff Indiana, LLC facility in Columbus, Indiana.

Utilizing innovative heat-treating techniques, our skilled team ensures these shears boast unparalleled strength, food-grade safety, and flexibility, making them indispensable across various sectors including food processing, industrial sewing, automotive, and more. Designed by an ergonomist, our handles prioritize comfort and efficiency, reducing hand strain during extended use.

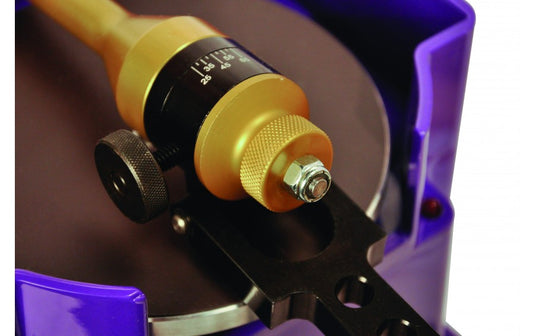

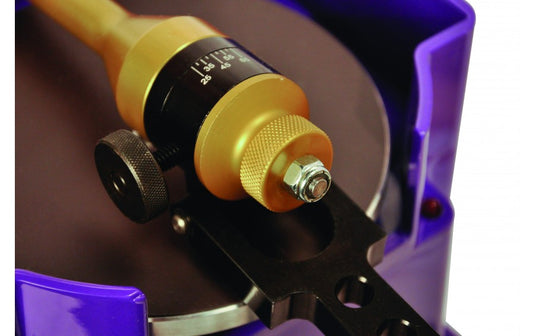

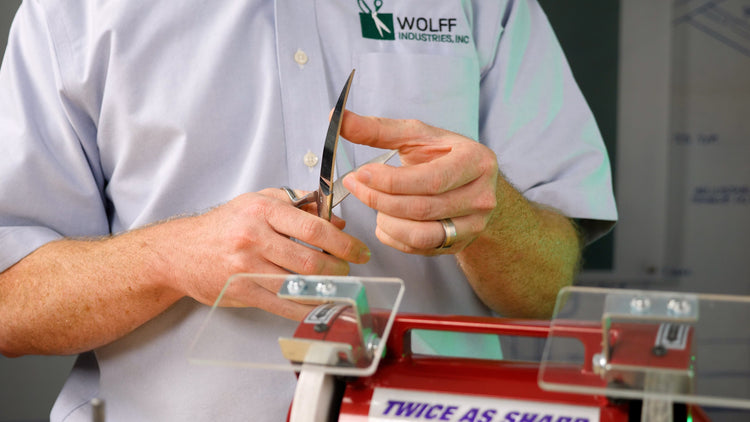

As the world's foremost manufacturer of industrial and professional scissors sharpeners, Wolff Industries, Inc. is committed to delivering premium stainless steel scissors and cutting-edge sharpening solutions, solidifying our reputation as the ultimate destination for all your scissoring and sharpening needs.

Benefits of Scissors from Wolff Industries

Our precision-engineered high-carbon stainless steel blades offer dependable performance.

High-quality construction delivers long-lasting sharpness for consistent and reliable cuts.

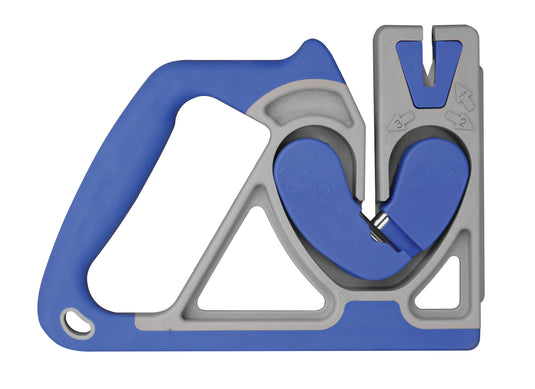

The Ergonomix® handles mold to your hand like a glove to ensure maximum cutting comfort.

What Is Ergonomix®?

Wolff Industries, Inc.'s Ergonomix shears stand out for their enhanced comfort, ease of cutting, prolonged sharpness, extended durability, and ability to minimize medical losses. The Ergonomix designation encompasses five specific criteria that shears must meet to be branded as such.

Designed By An Ergonomist

The handle design, a collaborative effort with an ergonomist, prioritizes proper hand ergonomics to maintain the operator's hand in the most natural position. Crafted from a soft thermoplastic elastomer, the handles alleviate stress and tension on the hand while being chemically bonded to the blades for enhanced durability and break resistance. This not only enhances comfort but also aids in reducing medical losses associated with hand injuries related to scissors usage.

The 5 Criteria of Ergonomix®

Crafted from resilient stainless steel hardened to a Rockwell C rating of 58, Ergonomix shears boast a life expectancy that is two to four times longer than those of our competitors. This longevity not only ensures sustained performance but also substantially diminishes your replacement costs.

Ergonomix shears operate with reduced hand pressure, as we have precisely set the blade tension to achieve optimal cutting performance.

Ergonomix shears have the pivot nuts mechanically locked in place with a nylon lock-nut to prevent loosening and falling off.

Ergonomix shears feature blades honed at a 35-degree angle, resulting in effortlessly smooth cutting and exceptionally durable edges. The honed edges not only facilitate a 40% reduction in hand pressure but also undergo meticulous hand testing to ensure the desired cut and feel. Every pair of shears must meet 100% of our stringent quality control standards.

Ergonomix shears are equipped with handles that are ergonomically designed to naturally position the operator's hand. The soft, thermoplastic elastomer handles contribute to minimizing stress and tension on the hands. Additionally, these handles are chemically bonded to ensure they are food safe and resistant to breakage.

Wolff® Scissors

How Our Scissors Are Made

How to Choose the Right Scissors

Additional Products

Shop by Industry

Scissors FAQ

We understand finding the perfect fit is crucial. If you're unsure, send us a sample of your material. We'll rigorously test different scissors to determine the ideal cutting solution for your needs.

We prioritize fast turnaround! Most of our professional shears ship out the same day you place your order.

Sharpening frequency depends on the abrasiveness of your material. It could range from daily to yearly. You'll quickly notice when your scissors need sharpening in a production setting.

Contact Us

Our knowledgeable representatives are ready to assist with your scissors and sharpener needs. They can provide customized solutions to your cutting challenges, offer expert product recommendations, and answer all your questions. Contact a Wolff Industries expert today for personalized support.